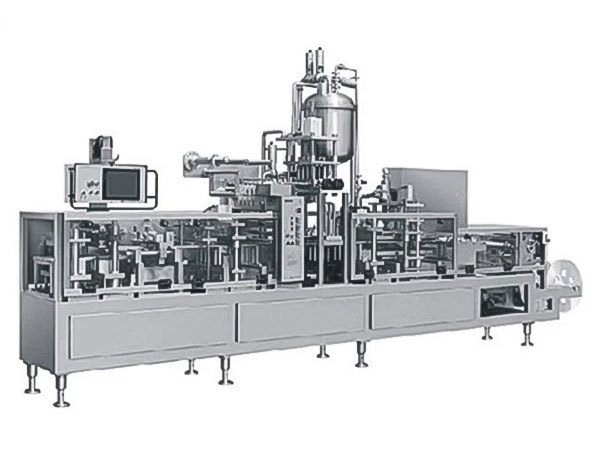

Aseptic Plastic Pouch Filling Packing Machine

Key words:

Aseptic Plastic Pouch Filling Packing Machine

Classification:

Key words:

Email:

- DESCRIPTION

-

- Commodity name: Aseptic Plastic Pouch Filling Packing Machine

Purpose of equipment

Equipment for a variety of fresh milk, yogurt, milk flavor, soy milk, fruit juice and other sterile packaging materials, automatic plastic bag sterilization, molding, aseptic filling, sealing and finished product delivery. The series of equipment can be applied to a variety of composite plastic film and aluminum, paper, plastic composite packaging materials. Equipment are the main components of international brands, stable operation, high sterilization efficiency, low energy consumption, is the first choice for the production of sterile long-lasting equipment.

The advanced two-sided free-standing aseptic bins, as well as the bag forming and filling system design, can simultaneously produce two different specifications of products, or carry out unilateral independent operation.

The dragging of packaging materials adopts three-stage fixed-length traction technology, adopts servo drive and photoelectric positioning, precise traction length, easy deformation of packaging materials, and is suitable for the production of various sizes of products.

The packaging material is soaked and sterilized by W-type movement in the H2O2 warehouse and dried through aseptic hot air to ensure the sterilization effect of the packaging material.

Sterile warehouse using H2O2 spray sterilization, high-intensity UV sterilization and sterile air replacement technology to ensure that the aseptic chamber sterile state is constant.

Sealing and cutting system driven by a servo motor, stable operation, high precision, fully ensure the finished sealing effect.

Through continuous liquid level controller and digital positioning valve control cylinder constant liquid level, the use of stepper motor diaphragm constant flow control of continuous filling to ensure accurate filling.

The latest single-station two-step sealing device (patented technology), to achieve a single station step by step heat sealing and slitting functions for a variety of aluminum, paper and plastic composite packaging materials, greatly extended The effective shelf life of the finished product.

Equipment integrated CIP and SIP systems ensure that piping and valves in contact with the material are sterileModel WJB-2D Capacity 8000 p/h (200ml) Volume 200-1000 (ml) Packing type Plastic pouch like pillow

Related Products

Leave us a message

Please leave us a message and we will contact you as soon as possible